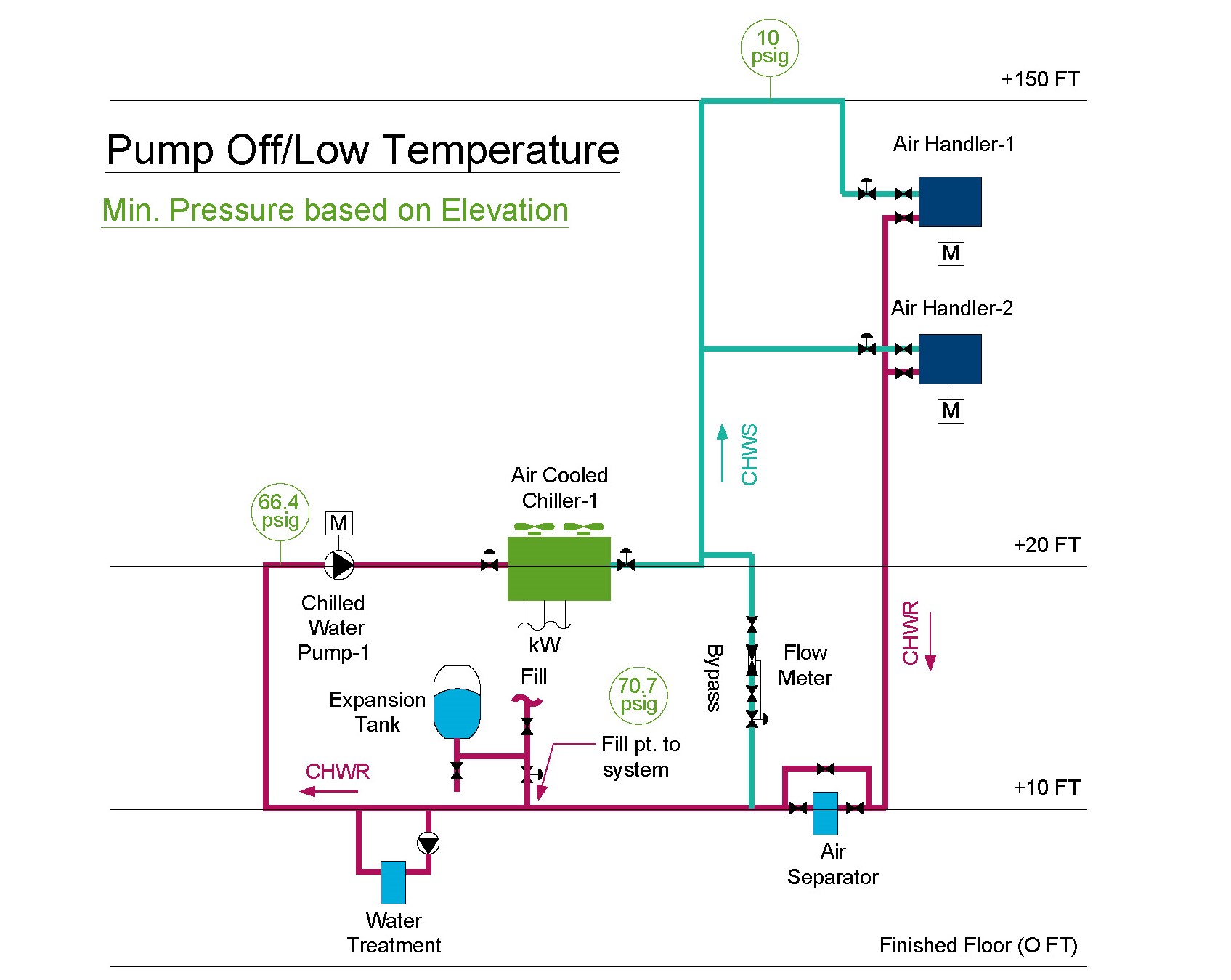

System flow below chiller min flow 250 gpm variable primary flow at 25 system load two way valves control capacity by varying flow of water in coils per chiller system load 50 tons 176kw 50tons 176 kw primary bypass flow 250 gpm 95 l s 150 gpm 9 5 l s delta t 12 of 6 7 oc 100 gpm 44 ºf 6 3 l s 6 7 ºc 56 ºf 13 3 ºc 150.

Schematic chilled water buffer tank piping diagram.

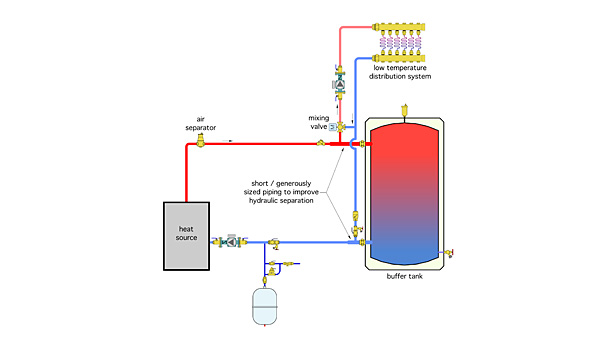

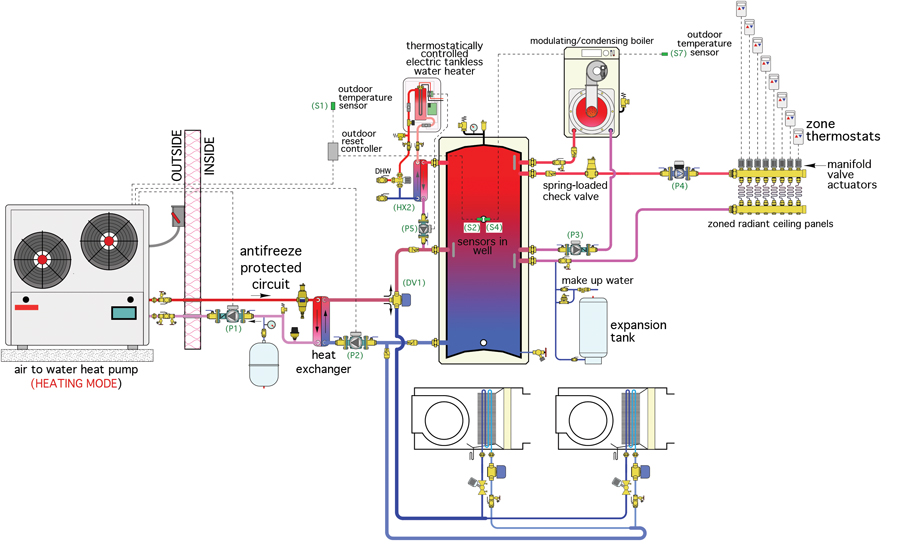

Buffer tanks for chilled heating water circuits.

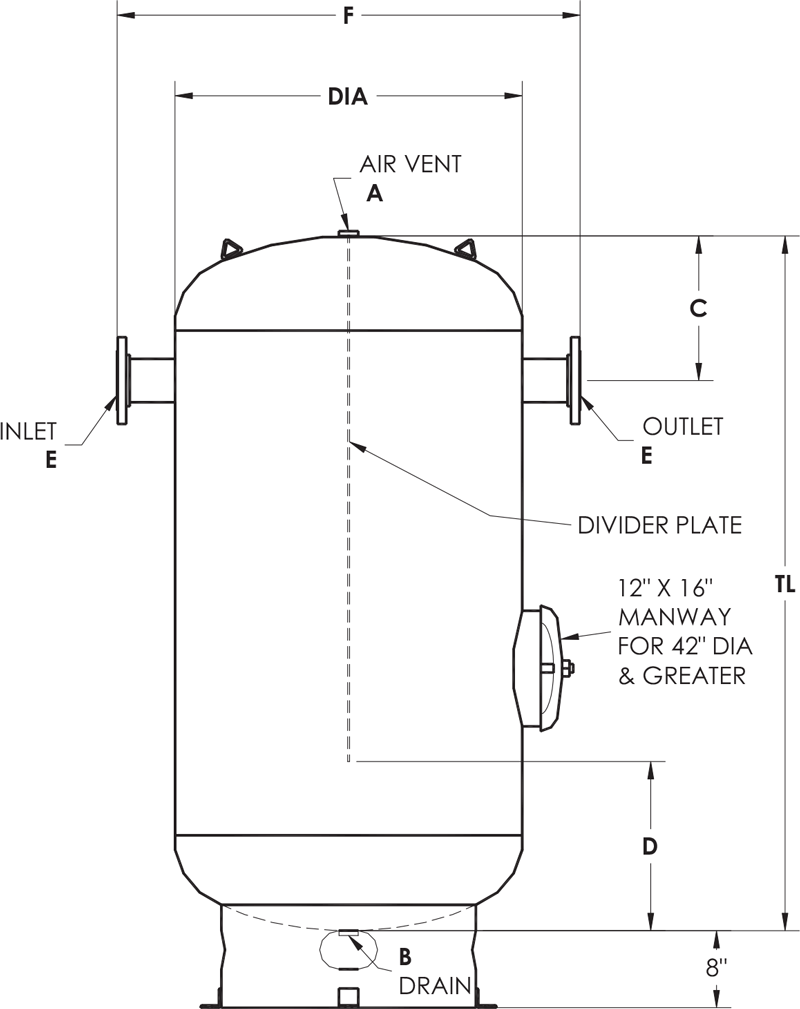

How is the water circulated inside the tank.

The unit is designed with an internal baffle.

Check with chiller manufacturer for specific requirements.

Typical hvac chiller systems are between 3 to 6 gallons per ton.

Po box 55 cheswick pa 15024 phone 724 274 5430 fax 724 274 5448.

In this article we l be covering chilled and condenser water schematics to learn how to read them how to identify the main components and symbols as well as real world examples additionally we ll cover the purpose of the main components and different design types.

As the system water enters the tank it is forced up and over the baffle before dropping back down to exit the tank.

Q where in the chilled water loop is the tank installed.

This ensures proper water circulation and full use of the tank volume.

By adding a buffer tank to the system extra volume is created which provides.

Volume of total buffer tank c x v r v a ton x gal ton gal required information for properly sized chilled water buffer.